You are here: Cops>Common Web>COPsProgram>DeepwaterHorizon (12 Mar 2018, RaymondLutz)Edit Attach

Deepwater Horizon Oil Disaster

Direct link to this page: https://copswiki.org/Common/DeepwaterHorizonLatest News

- 2010-06-23 - "Top Cap" suction pipe no longer engaged on top of wellhead, well is now gushing full-force with no containment at all.

Background

- BP Presentation detailing actions taken during the final hours of the disaster: http://energycommerce.house.gov/documents/20100527/BP.Presentation.pdf

- Drill pipe stuck in hole, cemented in place and sidetrack initiated.

- Drilling/logging finished the final completion a 7" x 9-7/8" casing string was run. It had just 6/21 centralisers. Not good bearing in mind the well was sidetracked.

- String was cemented in place.

- String was pressure tested after just 18 hrs, cement takes 48 hrs to cure, after 24 hours it has zero compressive strength. (The result is that the casing deflect radially under pressure, pushing against the cement).

- Cement bond was probably not helped by premature pressure test, cement job would be non-uniform due to lack of centralisers and off-vertical wellbore (following sidetrack).

- Gas migrates from formation through channels in the cement on the thin side of the annulus.

- Gas rises up the annulus unable to expand as the pack off is in place.

- 7"-9-7/8" casing approaches collapse as tension is circa 700,000lbf at the wellhead and formation pressure is rising up the annulus towards the wellhead.

- Casing survives collapse as unexpanded gas bubble nears SS-15 seal assembly, seal assembly lock ring fails under shear and seal is blown clean off the casing hanger and is launched up the wellbore directly at the BOP. (hand calcs show that the 100lb seal could have accelerated at near 800G on shearing free)

- Seal assembly enters the BOP like a giant artillery shell. Wrecking all kinds of havoc. Riser level is witnessed to drop, as annular is damaged.

- BOP fails and gas migrates up into the riser.

- Flow is totally masked as A) mud is being returned directly to the boat to save time, B) pumps are being run up/down as seawater is displaced.

- Gas plume accelerates up the riser, before spilling out in huge quantities and finding an ignition contact within minutes if not seconds.

- Rig engulfed in flames

- EDS (Emergency Disconnect) system activated

- Rig abandoned.

- Coast Guard turn up and deluge fire.

- Deepwater Horizon sinks

- Marine riser buckles and breaks

- Massive oil spill ensues.

- BP Engineering of the well, the well had a bad design, too few centralisers made the cement job vulnerable to gas migration. This problem was totally compounded when the well deviated from theoretical true vertical when they suffer with stuck pipe and were forced to sidetrack.

- BP completion of well, the last few steps to complete the well included several key oversights.

- Mud transferred directly to the boat. (making it impossible to measure volume in/out)

- Failure to log the cement job. The guys on the rig making decisions failed to grasp that the cement job was seriously undermined by a pathetic casing program (6/21 centralisers) and the sidetrack, but that wasn't their job. They made their own assumptions based on the assumption the BP Engineers had done their job correctly, they had not.

- Failure to install the lock down sleeve promptly. The guys on the rig had made a decision to delay running the lockdown sleeve as they assumed they had a good cement job. If they had a good cement job the lockdown sleeve was a back up component.

- The fire would have burned fiercely above the drill floor and would have eventually consumed everything from there up.

- Is it possible that the pontoons, the rig legs and the drill floor could have survived the fire for a week or two or maybe even more?

- Is it possible that the riser could have maintained intact for many days after the blowout? Simply feeding oil and gas to a giant inferno above the rig.

Technical Information

- VERY GOOD: http://www.whoi.edu/fileserver.do?id=64023&pt=10&p=43992 -- "Considering Technical Options for Controlling the BP Blowout in the Gulf of Mexico" -- Written by James Cameron and Members of an Ad Hoc Deep Ocean Group after meeting in Washington, D.C. June 1, 2010 -- Includes background and options. Important comments:

- There was concern that capping the flow at the BOP or significantly raising its internal pressure to drive the mud down against formation pressure of about 13,000 psi (based on mud weight of 14 PPG at TD of the well,) might create an underground blowout at the last casing section. When it was established that the casing shoe on that casing string was at approximately 17,000’ (12,000’ below seafloor), this concern was deemed minimal and the value of shutting in the well was sufficient to recommend proceeding with a restriction/top kill approach.

- the maximum pressure within the BOP that they deemed safe— reported to be 8,000 psi. If BP were able to sustain pressures approaching this limit on the prior attempt, then further attempts to perform a top-kill are pointless.

- For more than a day, the drifting ship exerted enormous bending forces on the base of the BOP, possibly in a circular manner as currents changed. These forces flexed the BOP in different directions, further weakening it.

- Animation of drilling operation showing placement of seals. -- http://www.dril-quip.com/ss15bb.htm

- Article explains that BP's oil drilling operation may be over a massive bubble of methane and the string of events may culminate in an even larger catastrophe, and that with current engineering technology, it is impossible to contain gas at pressures over 100,000psi, and that the gas will continue to leak through the ocean floor. -- http://www.helium.com/items/1864136-how-the-ultimate-bp-gulf-disaster-could-kill-millions

- From The Oil Drum http://www.theoildrum.com/node/6597#comment-654709

- It is open to interpretation whether the oil seeps shown (taken by the ROV) is just oil that were being stirred up or something else.

- It is not in dispute that the BOP is tilted.

- It is BP's contention that the BOP was bent by the collapsing riser.

- It is not inconceivable that with the bent, something cracked --- which would account for the minute amount of oil seepage.

- It is not in dispute that BP placed the inclinometer on the BOP to monitor any changes in its orientation.

- With the "cap" on it and additional work, it is not inconceivable that additional stresses can be placed on the BOP.

- Whether it will lead to catastrophic failure --- we have no public information.

- We do, however, know that sand is coming up with the oil and gas and gradually weakening the entire well structure.

- On a balance of probabilities --- I would say, watch it closely, but there is not much that can be done to stop or slow the failure if it does happen.

- The only thing I can think of is to be real careful putting additional stresses on the stack.

- Skimming ships from The Netherlands -- http://www.koseq.com/

- Initially turned down by US and BP: http://www.csmonitor.com/USA/2010/0601/BP-oil-spill-Will-the-sweeping-arm-system-from-the-Dutch-help

- US safety and regulations laws at first prohibited the use of these skimmers, due to the fact that they collect an oil/water mixture and separate the oil from the water. The water is then pumped overboard, of course with some petroleum particles still in it. US laws demand that all the oil/water collected must stay aboard on the ship, because it is unlawful to pump water with oil residue in the Gulf.

- One ship with two skimmers can collect up to 250.000 liters of oil out of the water PER HOUR. That is netto oil, so without the water. Their water cut is aprox. 30% in this system. So, lets say 4 ships with skimmers, each collecting 250.000 liter of oil per hour, is 1 mil. liters times 24 equals 24.000.000 liters per day. That is aprox. 150.000 barrels of oil per day.

- Must not use dispersants or skimmers do not work!

- Leaks around the wellbore: (http://www.theoildrum.com/node/6597#comment-654748)

Ideas:

- Ideas from readers of BBC News: http://news.bbc.co.uk/2/hi/world/us_and_canada/10268979.stm

Images

%IMAGEGALLERY{titles="off" columns="6" warn="off"}% (Just attach your images to this topic and they will automatically be added to the gallery above!)Timeline

See http://online.wsj.com/article/SB10001424052748704302304575213883555525958.html for a great timeline.- 2010-04-20 - Deepwater Horizon drilling platform explodes, burns, killing 11 people on board.

- 22 Apr 2010 -- Transocean Deepwater Horizon drilling rig sinks. Spill starts.

- 24 Apr 2010 -- 32 spill response vessels (skimmers, tugs, barges, recovery vessels).*

- 29 Apr 2010 -- 69 response vessels are being used including skimmers, tugs, barges and recovery vessels.*

- 07 May 2010 -- First containment dome is lowered to try to suck up the oil from the damaged riser pipe.

- 08 May 2010 -- Containment dome fails, clogged with hydrate "snow"

- 10 May 2010 -- "Top Hat" containment dome planned. "Junk Shot" announced.

- 16 May 2010 -- Insert tube into broken pipe to siphon off some of the oil to the surface.

- 17 May 2010 -- BP begins burning off gas siphoned from the broken pipe.

- 19 May 2010 -- Heavy oil begins to wash up on Louisiana coastline.

- 26 May 2010 -- BP announces plan to "top kill" the leak using heavy drilling mud and cement.]

- 30 May 2010 -- BP stops Top Kill effort after three attempts and 30,000 bbls of mud is pumped.

- 31 May 2010 -- Third attempt started, involving cutting off riser pipe and placing cover on top.

- 03 Jun 2010 -- Second cut completed on riser pipe.

- 06 Jun 2010 -- Oil is pumped to a tanker on the surface, about 10,500 bbls of oil collected, but cap leaks terribly.

- 23 Jun 2010 -- "Top Cap" suction pipe no longer engaged on top of wellhead, well is now gushing full-force with no containment at all.

- 2010-06-19 -

- Approximately 31,000 personnel are currently responding to protect the shoreline and wildlife and cleanup vital coastlines.

- More than 6,200 vessels are currently responding on site, including skimmers, tugs, barges, and recovery vessels to assist in containment and cleanup efforts—in addition to dozens of aircraft, remotely operated vehicles, and multiple mobile offshore drilling units.

- Approximately 2.42 million feet of containment boom and 3.77 million feet of sorbent boom have been deployed to contain the spill—and approximately 492,000 feet of containment boom and 2.03 million feet of sorbent boom are available.

- Approximately 22.3 million gallons of an oil-water mix have been recovered.

- more than 225 burns have been conducted to remove more than five million gallons of oil from the water.

- 2010-06-23 - suction pipe no longer engaged on top of wellhead, well is now gushing full-force with no containment at all.

Recent Articles and Media: (Add | All Media)

This is the most recently published 20 articles, most recent first.-

(M993) 2010-06-24 'Full Containment' plan to stop the Deepwater Horizon leak -- Raymond Lutz, Citizens Oversight,

(M993) 2010-06-24 'Full Containment' plan to stop the Deepwater Horizon leak -- Raymond Lutz, Citizens Oversight,

-

(M994) 2010-06-23 'Full Containment' Plan News Release -- Raymond Lutz, Citizens Oversight,

(M994) 2010-06-23 'Full Containment' Plan News Release -- Raymond Lutz, Citizens Oversight,

-

(M992) 2010-06-18 Deepwater Horizon Oil Spill 'Full Containment' Plan - Whitepaper submitted to DHS -- Raymond Lutz, Citizens Oversight, Deepwater Horizon

(M992) 2010-06-18 Deepwater Horizon Oil Spill 'Full Containment' Plan - Whitepaper submitted to DHS -- Raymond Lutz, Citizens Oversight, Deepwater Horizon

Forums and Comments:

- See http://www.theoildrum.com/node/6597 for a forum where much of this information was derived.

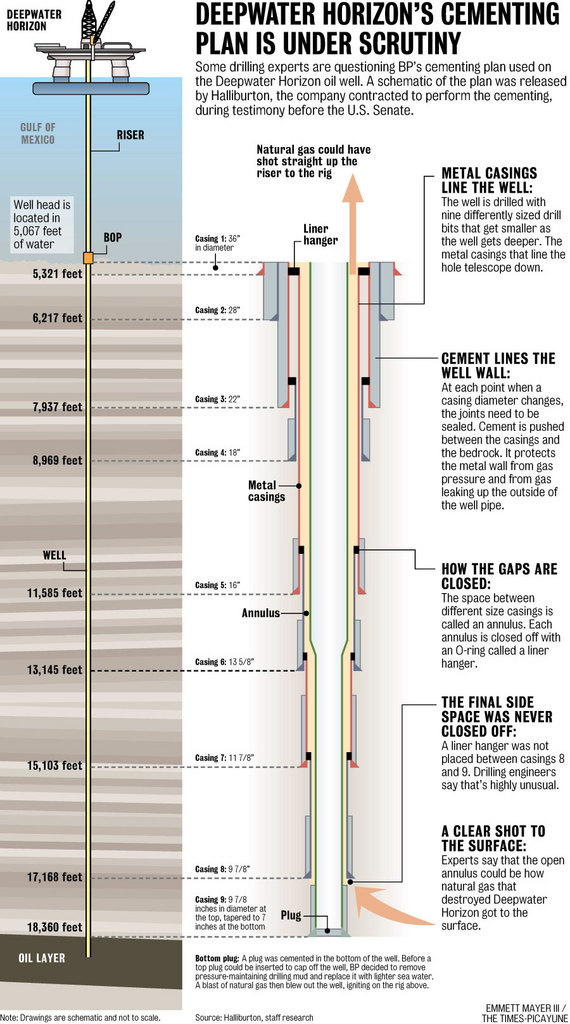

- Description of the drilling by Halliburton cement operation:

- oil-cause-050710.pdf: Description of the oil disaster -- "WHAT HAPPENED ON THE

Comments

Project Form edit

| Project Name | Deepwater Horizon Oil Disaster |

| Project Description | Background and ideas for dealing with this disaster |

| Project Founder | Raymond Lutz |

| Project Curator | Raymond Lutz |

| Project Type | Issue Oversight |

| Project Parents | |

| Related Keywords | |

| Project Status | Closed |

| Thumbnail Link | |

| Forum Link | |

| List Serve Topic |

| I | Attachment | Action | Size | Date | Who | Comment |

|---|---|---|---|---|---|---|

| |

oil-cause-050710.pdf | manage | 306 K | 26 Jun 2014 - 21:23 | Raymond Lutz | Description of the oil disaster |

| |

oil-halliburton-cement.jpg | manage | 144 K | 26 Jun 2014 - 21:23 | Raymond Lutz | Description of the drilling by Halliburton cement operation |

Edit | Attach | Print version | History: r11 < r10 < r9 < r8 | Backlinks | View wiki text | Edit wiki text | More topic actions

Topic revision: r11 - 12 Mar 2018, RaymondLutz

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors.

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors. Ideas, requests, problems regarding Cops? Send feedback